|

There is a wide variety of gate types depending on the needs of your project. Following is a few examples of the most common types. Click on an image to view a zoomed version of that specific gate.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

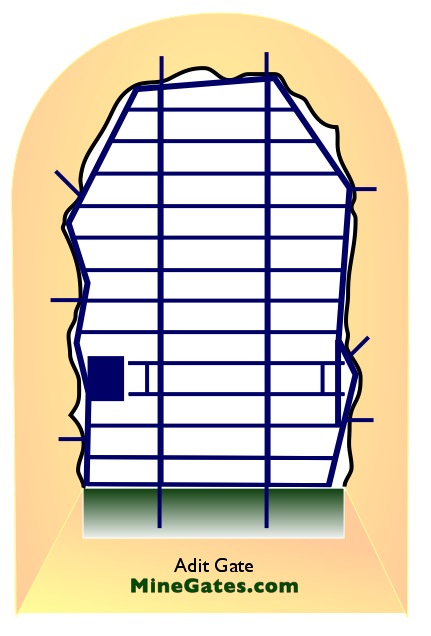

Standard Mine Adit Gate

This is an example of a bat friendly Adit Gate. This gate uses Jail-style, high strength manganal steel bars. Manganal steel gates are often used in remote site where the overall gate weight makes transportation difficult. The horizontal bars have a gap of 5 3/4 inches so that large bats have enough room to fly through the bars. This size also is small enough to exclude humans from squeezing through. The horizontal bars are smooth and rounded to help avoid any damage to the bats flapping wings as they pass the gate. This gate can be built out of a variety of steel variations depending on the security circumstances of the site. The entrance to the gate is through a set of removable bars toward the bottom of the gate. The width of the open gate vertical bars is wide enough to pass a rescue stokes in case of an emergency. The height of the entrance makes it easy to step through the opening. The padlock is protected by a steel plate box that also acts a receiver for the two removable bars. The gate is held in place with pins in the walls, and a deep concrete footer is placed in the floor to dissuade digging under the gate.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

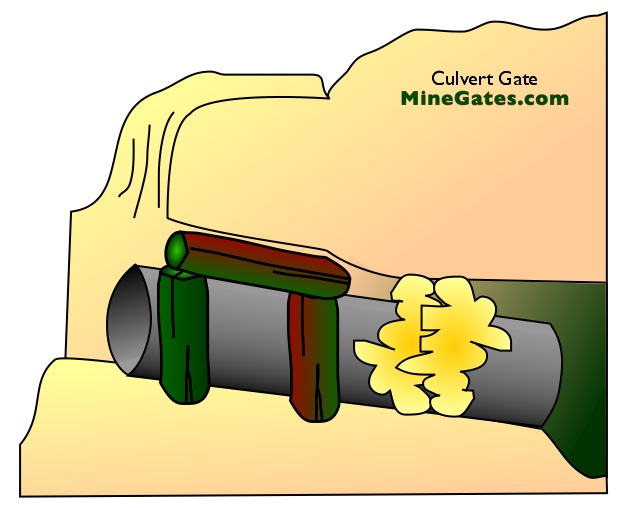

Culvert Gate

This diagram is a side view of a Culvert Gate. This type of gate is normally used when the opening is unstable or consists of loose fill material. Note in this example there is old shoring beams that will ultimately collapse. The yellow material around the culvert pipe is expansion foam. This foam is normally backfilled with dirt and rock on either side of the tunnel. The gate resides inside the steel culvert normally at a point near the inside end of the pipe. The diameter of the pipe depends on the site specifics, but normally is in the range of 2 to 5 feet.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

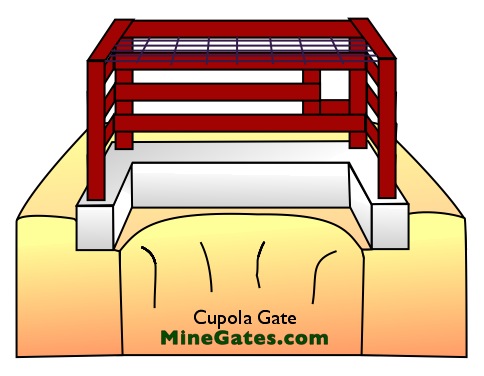

Cupola Gate

The Cupola Gate is used to cover vertical shafts. This diagram cross-section shows the basic design of the gate and how is sits above an open mine shaft. Bats using this type of entrance will fly horizontally through the bars for access. The steel gate structure is mounted on top of a concrete footer that helps stabilize the loose material around the mine shaft. Normally this footer is built during installation, but sometimes mines shafts have existing collars that gates can be mounted upon. Note that this version has steel meshing on top of the gate and an Owl access window.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

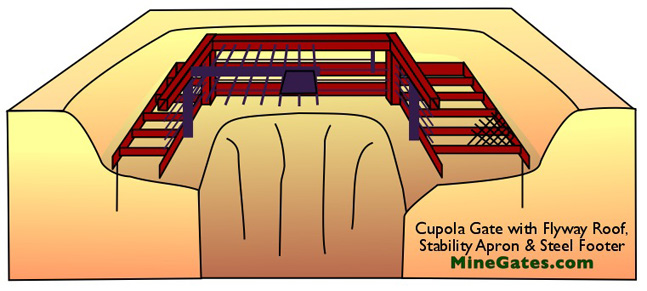

Cupola Gate with Flyway Roof, Steel Footer, & Stability Apron

This variation of Cupola Gate uses an open Flyway Roof so that the bats can fly vertically out of the mine shaft. An advantage to this design is that the bats do not have to slow down to make a turn out of a covered top cupola, which helps avoids predation at the gate. This Cupola gate also uses a steel footer in place of the more traditional concrete footer. This simplifies onsite installation process. Another unique feature of this gate is the Stability Apron that is used on sites where the mine shaft collar is composed of weak unconsolidated fill or collapsing materials. The back right corner of this design includes an Owl window.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

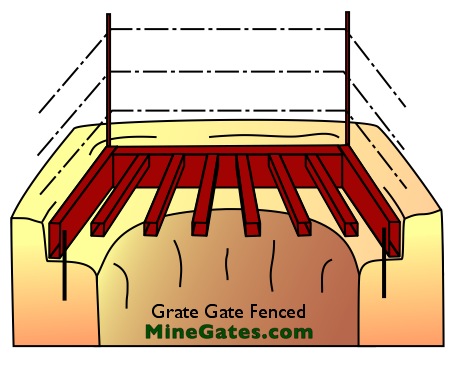

Grate Gate with Fence

This gate is used for covering vertical shafts, and is one of the most cost effective bat-friendly solutions. This variation sits atop the shaft collar, but can also be recessed inside the shaft if there is solid rock for attachment. Bar spacing is the standard 5 3/4 inch which enables bats to fly vertically out of the shaft. An advantage of this design over cupola gates is that the bats do not have to slow down during the gate exit, thus avoiding possible predation at the gate. The gate in this diagram is also using a steel footer instead of concrete, and mounted to the ground with pins. The fence poles are welded directly to the gate frame to keep them stable in snow conditions. The fencing keeps out large ungulates and inattentive hikers.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grate Gate Covered

In this variation of Grate Gate there is a mesh of steel covering most of the gate. A vertical bat window is left open in the center of the gate. The mesh is a safety barrier for large animals and humans so that they don't accidentally place their foot between the main gate bars. This gate works well for a small colony of bats since the flyway is somewhat restricted. Medium sized colonies of bats would require a Fenced Grate Gate, and large colonies would best be served with a cupola gate with a Flyway Roof.

|